Student : Adar Adler

Advisor : Professor Adin stern

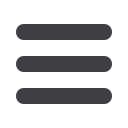

+-45

22.5/112.5

30/120

37.5/127.5

7.5/97.5

15/105

0/90

Dr Dana Ashcenazi -School of Mechanical Engineering, Tel

Aviv University

Dr Yair & Idan Rosenthal - Materials Engineering

Department, Ben-Gurion University

Dor shabat -Department of Mechanical Engineering, Afeka

For providing the facilities, materials & information making

this research project possible.

Orientation based print flues was characterized and can help

post processing

Different build orientation

will effect part’s fill type

result different measured

deviations.

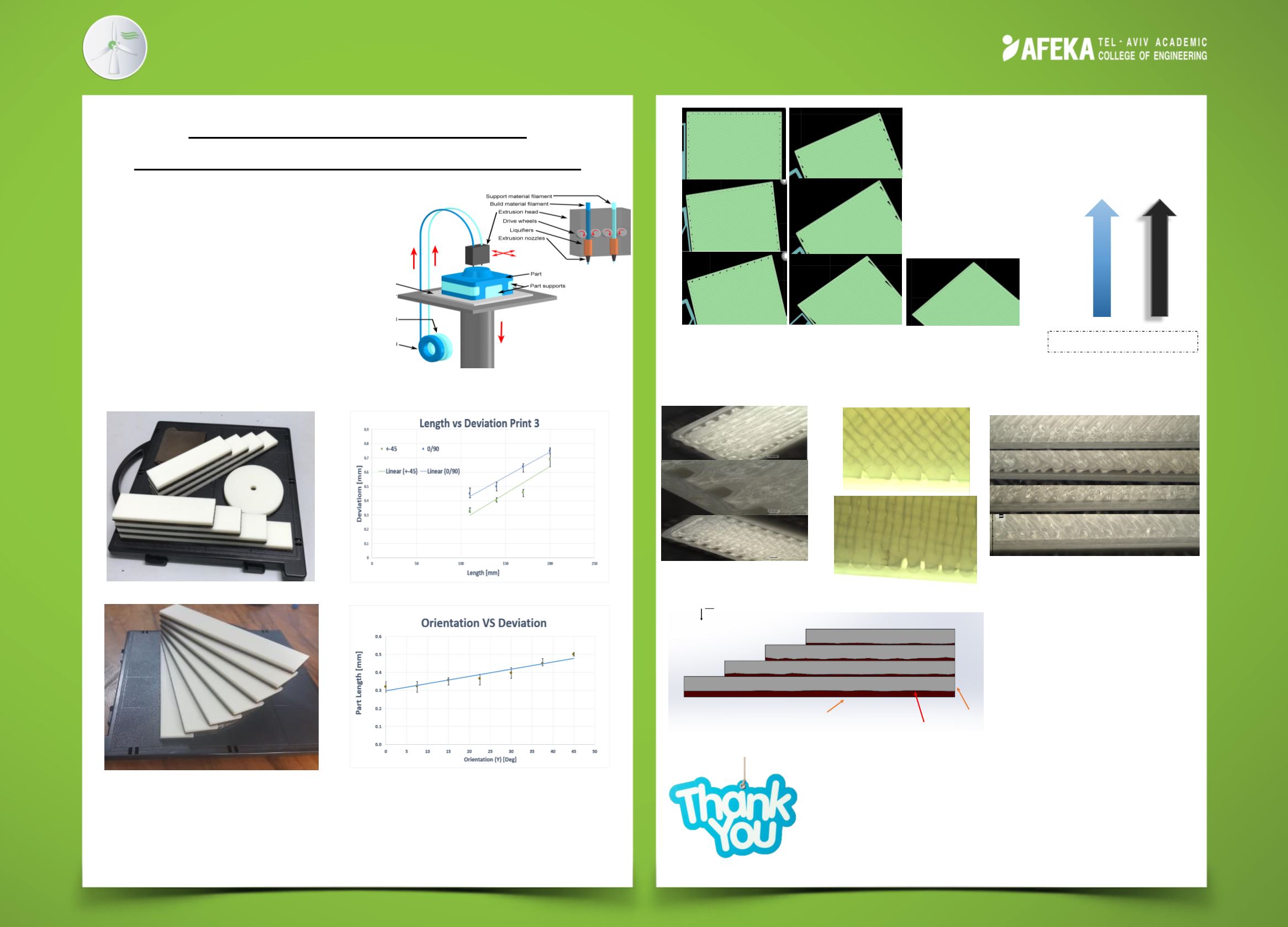

Bad surface roughness

in the bottom of the

printed model

Support material

Structural

material

mg

200

170

140

110

Dev Grow

Mass Grow

Deviation

Mass

Surface roughness can

be predicted by part’s

built orientation

Research Project – 3D Printing

Building Strategy &

Geometric Tolerances

A linear function showing measured deviation of printed parts

built in different orientation resulting different fill type pattern

The present study deals with the

influence of printing parameters and

orientations on Dimensional Accuracy

of 3D printed ABS samples using the

FDM technology; the results may help

the printer’s technician to minimize

geometric deviations by choosing the

suitable building orientation.

Mechanical Engineering