AM- Study of mechanical features of polymer

models depending on the printing process

parameters using Bending and Fractography tests

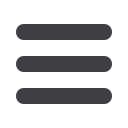

Experimental

Three printing tray were printed to check the influence of different parameters on the

mechanical properties. Standard ASTM D790 3

-

point bending specimens (Fig. 2) were printed

and used to study the possible effects of some printing parameters on the mechanical

properties of the printed material. Visual testing (VT) and light stereoscopy (Fig. 8) observations

were carried out to study the possible defects and define the quality of the printed specimen`s

surfaces and for initial characterization of the fracture surface. For further understanding

purposes fractography examinations of the fractured specimens (Fig 7.) followed the mechanical

tests.

Figure 1.

First tray (Fig. 3) :

Two parameters were

evaluated: (a) possible effects of building

direction; and (b) influences of the location of

the specimens on the printing tray.

Figure 3.

Second tray (Fig. 4) :

Two parameters were evaluated :

(a) bending specimens were printed

in different locations in the Z direction

(various heights from the XY plane)

and (b) along the 45 degrees direction

in the XY plane.

Figure 4.

Dor Shabat

Advisor: Professor Adin Stern

Mechanical Engineering

Third tray (Fig. 5) :

specimens were built in different angles to the XY plane: 15, 30, 60, and 75

degrees.

Figure 5.

Results and Conclusions

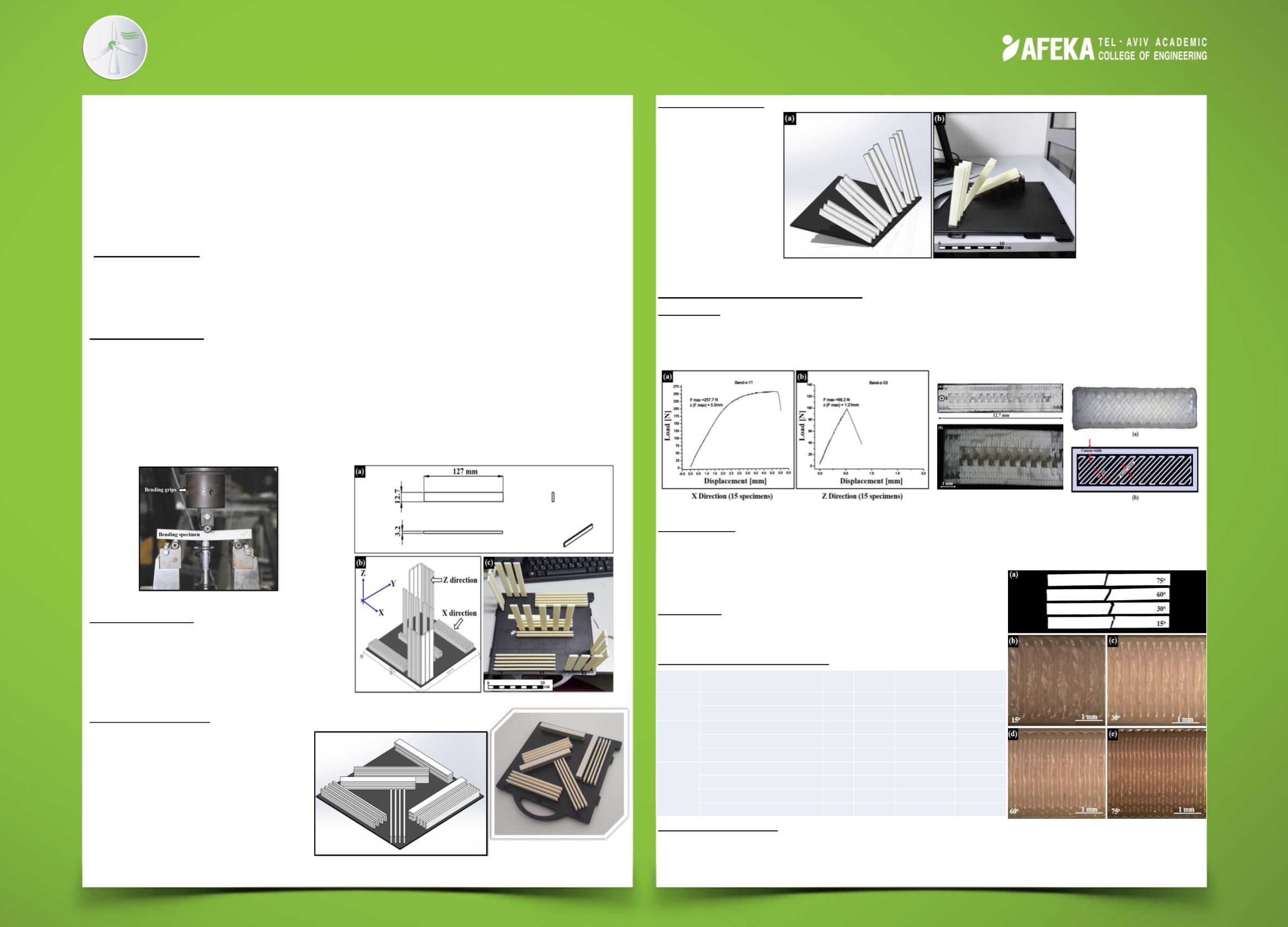

First tray :

Specimens built in the X-axis direction (the long axis of the specimens is directed

towards the tray`s X direction, 0 degrees relatively to the X-Y plane) exhibited higher strength

(maximum load and stress) values, by a factor of 2.5, compared to the strength measured on

bending specimens built in the Z direction (Fig. 6).

Figure 6.

Figure 7.

Second tray :

It was observed that there is no difference in bending properties obtained from

specimens at similar positions and from those printed in different heights along the Z-axis. Also,

no difference was observed in bending deflection specimens printed in the XY direction as

compared to those printed at 45 degrees to the main axes.

Third tray :

It is shown that high-angled specimens have

Smaller maximum bending stress and displacement values

comparing to low-angled bending specimens.

Summary of Bending Results :

Acknowledgements :

Figure 8.

Dr. Ashkenazi D. – Tel Aviv University; Rosenthal Y. – AFEKA; Tourgeman A. – NRCN; Berger A. –

HP; Adler A. – AFEKA.

The Purpose

This project explores possible effects of some 3D-printing parameters on the mechanical

properties in bending (Fig. 1) of ABS plus© in order to gain better understanding on this new

manufacturing method.

Max. Bending

Stress [Mpa]

Max. Displacement

in Bending [mm]

Max. Bending

Load [N]

number of

models

Parameters

58.2

4.5

250.4

15

Bild direction - X - 0 degrees

First

printing

23.4

1.2

100.6

15

Bild direction - Z - 90 degrees

46.7

4.1

201.0

16

Build direction - X/Y

Second

printing

49.8

5.3

214.3

6

printing 3 floors - 0/90 degrees

42.0

2.6

180.8

3

printing 3 floors - 45 degrees

57.4

4.5

247.0

3

printing angle degrees - 15 degrees

Third

printing

51.8

3.4

222.7

3

printing angle degrees - 30 degrees

34.5

1.8

148.3

3

printing angle degrees - 60 degrees

29.5

1.4

126.7

3

printing angle degrees - 75 degrees

Figure 2.