The Problem:

The netted-belt cylinder acts as a support wheel for a very wide belt that is made out of a fine

nylon net. This netted-belt rotates at varying speeds between 800 and 1000 [m/min]. The

customer wishes to change the angle at which the netted-belt meets an identical netted-belt

from below. In order to achieve that, the netted-belt cylinder must be able to change its

position. The cylinder is 6 meters long and weighs 4000 Kg and because it acts as a support

wheel it needs to lowered/raised in a completely horizontal manner. Otherwise the netted-

belt might slip off.

The Main User Specified Request:

Having real-time control, in an accurate manner, over the angle at which the lower and upper

netted-belts meet each other.

The Main Objective:

Developing a parallel lifting/lowering apparatus for a netted-belt-cylinder, in an accurate

fashion according to the will of the operator and during manufacturing.

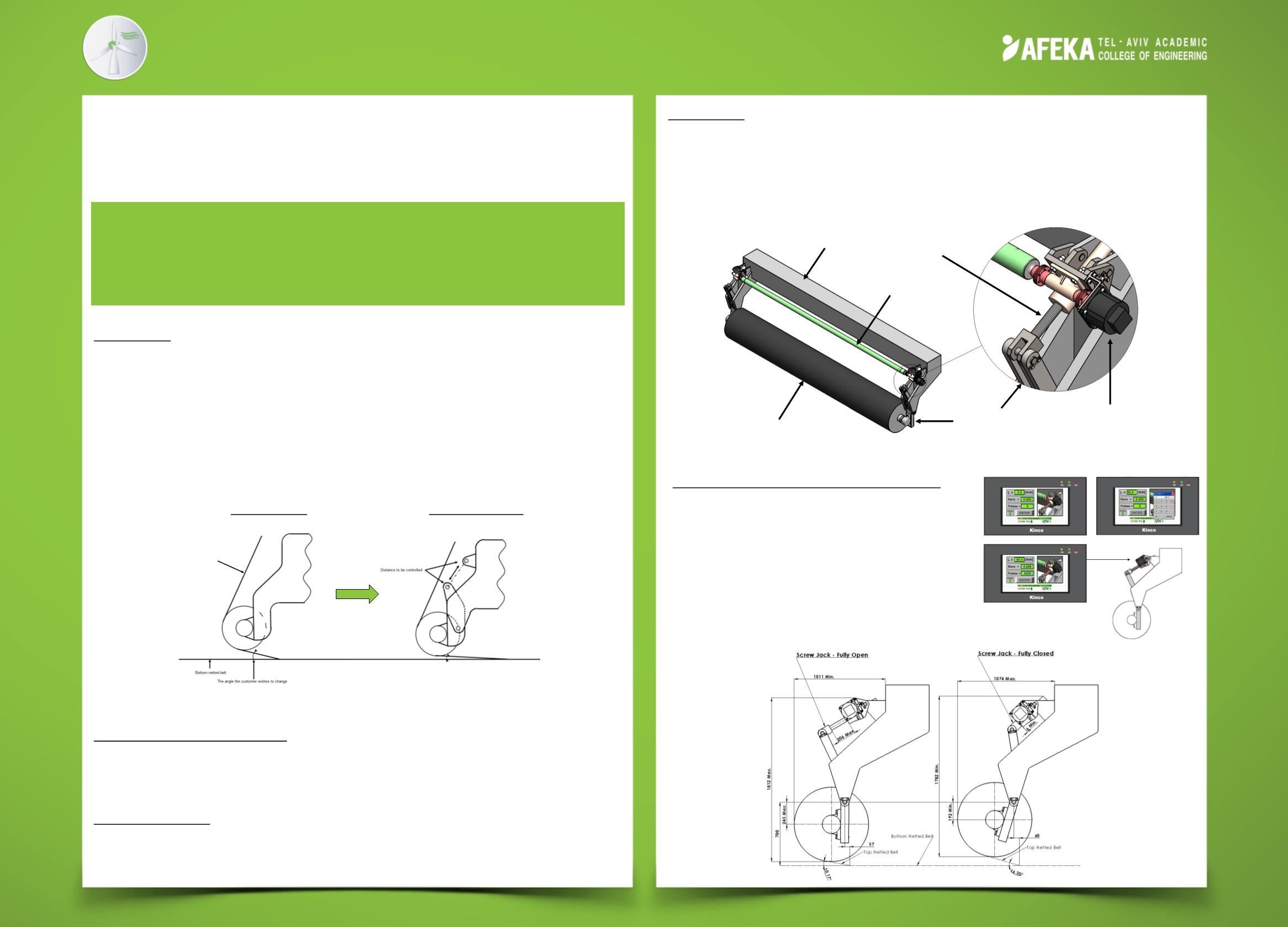

Operating The Parallel Lifting Apparatus - HMI:

1. Click on the field “L = _ [mm]” to open up a

number keyboard.

2. Enter the desired length for the opening of the

screw-jack.

3. Press “ENTER” and the motor will begin to rotate.

Parallel Lifting Apparatus for a Netted-Belt

Cylinder

Jair Barzilay

Advisor: Mr. Assaf Vilenski

Mechanical Engineering

The parallel lifting apparatus is designed to horizontally

lower/raise a rotating cylinder which is 6 meters long and

weighs 4000 Kg. It is operated through an easy to use touch

screen HMI.

Upper netted-belt

Static System

Dynamic System

The Solution:

The netted-belt cylinder is mounted on two swinging arms which are actuated by a set of two

screw-jacks, one on each side, that are connected through a driving shaft. A screw-jack is a

mechanical device which transforms torsional torque into a pulling or compressing force. The

screw-jack on the right side is connected to a servo-motor which is controlled through an HMI

touch-screen side panel.

Screw-Jack

AC Servo-Motor

Swing-Arm

Netted-Belt Cylinder

Stationary Frame

Driving Shaft

(3)

(1)

(2)