Method for creating custom made insoles based

on pressure simulations

Jonathan Porat

Advisor: Assaf Gur

Medical Engineering

The project’s essence is to design a new method of

creating custom made insoles based on plantar

pressure measurements taken from simulations.

As of today, many of the insole manufacturers create are based on

geometric dimensions only, by using the foam method or the

plaster casting method. These methods do not provide any

adjustments based on the patient’s plantar pressure and seem to

be outdated compared to today’s technological advancements.

The aim of the project is to design an enhanced theoretical insole.

The insole’s dimensions will be based on optimizing, as much as

possible, the patient’s planter pressure, as compared to the

pressure distribution over healthy feet.

Summary

In order to decide the dimensions of the insole based on pressure

simulations, we needed to know what is the standard plantar

pressure distribution of healthy people. We were able to find these

values in a study conducted with 92 healthy participants. The

participants’ plantar pressure measurements were then averaged

and normalized to percentages of total weight. We are going to use

these average values of different points of the feet to help us decide

what height different locations of the insole should have.

Literature Values

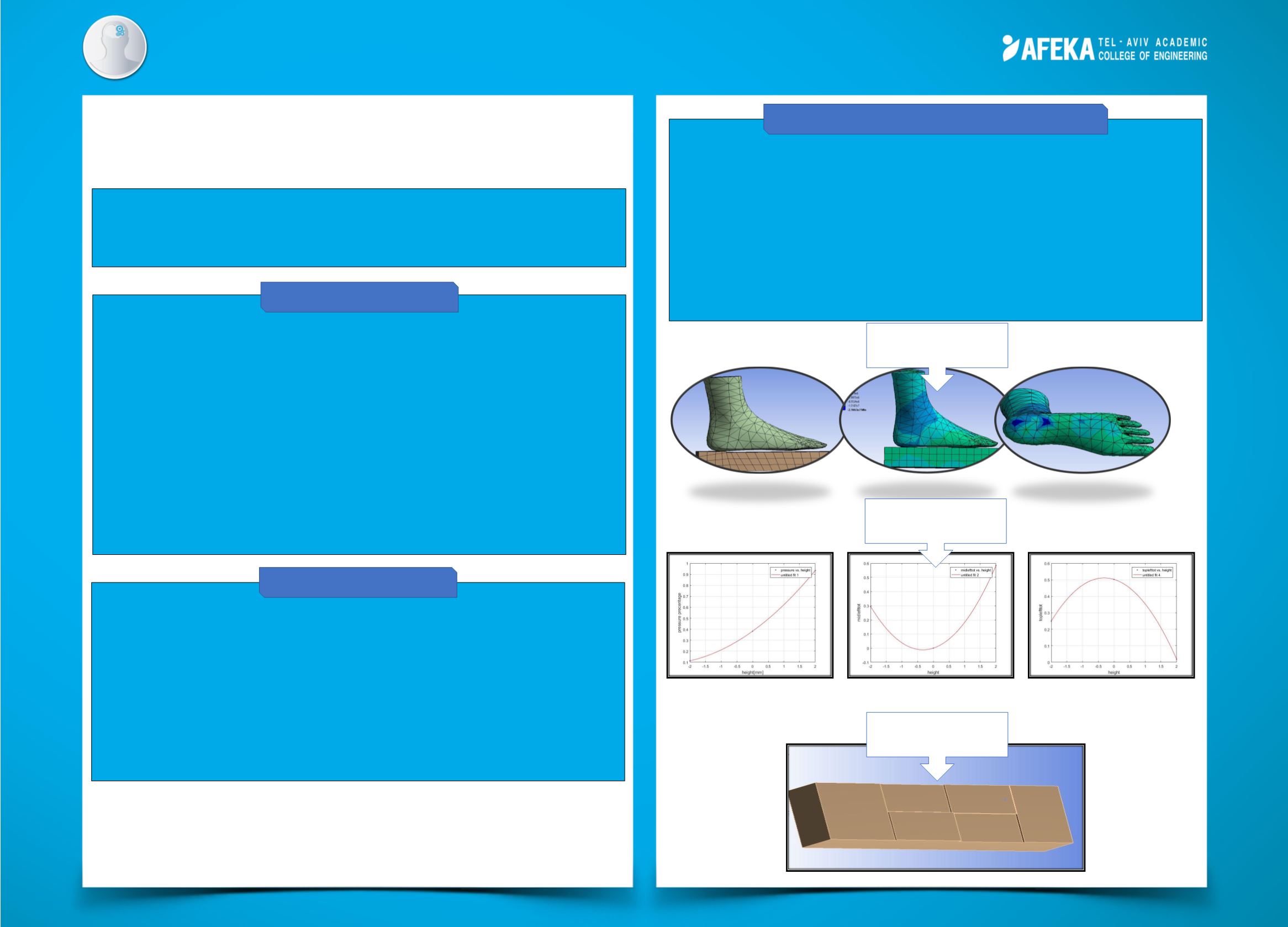

We obtained a model of a human foot that would be the patient in

our simulations. Then, based on 11 different simulation where we

changed the height of different locations under the foot, we were

able to extract pressure measurements and use them in an

algorithm that finds the correlation between the height of the platform

and the pressure on the feet. Once we have this correlation we can

decide what are the heights required at each point in order to get the

wanted values of pressure.

Simulations and algorithm

Simulations

Correlation

Result