Development of an auxiliary system for a Gas

Turbine start-up which enhances reliability and

minimizes maintenance costs

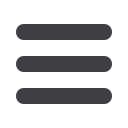

We simulated the process of the gradual pre-heating by 4 consequent runs of transient heat

transfer analysis, the software used is a thermal model of Solidworks.

The 4 steps of heating are presenting as follow:

Atalya Glass

Advisor: M.Sc. Boris Lash

Mechanical Engineering

The main practical goal of this project is to reduce as much as

possible the harmful influence of the radical temperature

changes on the sensitive components life cycle during

startup time. This project deals with the development and

modeling of a fast start up system that provides a suitable

solution for the problem.

1

4

3

2

.1

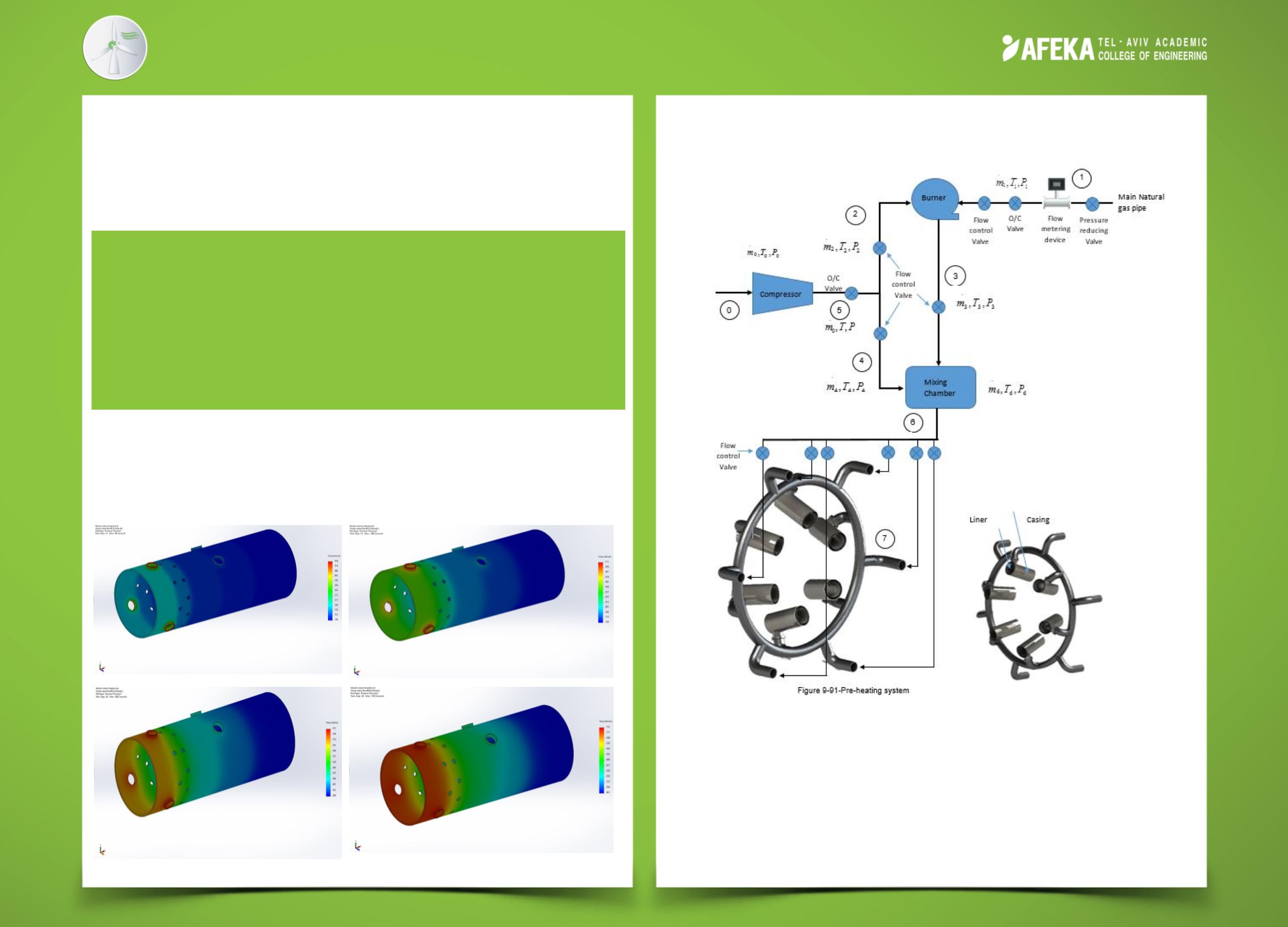

Schematic Pre-heating System Design

.1

Results:

We get to see by the results that the preheating system is

effective in order to deal with the problems created by

temperatures deflections and also saving economic costs

(20,000$ savings per year).

.1